Table of Contents

Six Sigma Green Belt helps in better operational procedure. It is a popular operation management tools. What do you understand from the term operation management.

Operations management means defining, analyzing, improvement and control the operating system of the project.

Here are the 10 benefits of Six Sigma for operations of management professionals in

2021.

1.Eliminate errors and defects

Six Sigma Green Belt tools help you to recognize errors and defects in a project. This helps the organization to avoid unnecessary conflicts in the project. The organization that has a team of six sigma certified performs better than noncertified.

- Maintain the quality and sustainable development of the organization

When you have a team of Six Sigma certified then you don’t have to worry about the organization project. The benefit of six sigma certification is you can analyze the company’s working process and can take steps to improve it. With the help of the six sigma team company can maintain the quality, and also development will be sustainable. - Minimize Operation Cost

High-cost results in a profit of the organization and even it go into debt. When you eliminate unnecessary errors and defects. It automatically saves the extra cost that occurs with the six sigma green belt tool.

4.Customer Satisfaction

Nothing will help you grow your business if your customers are not happy or satisfied with your product and service. How to analyze whether your customers are happy?

This job will be done by your six sigma team. The product or service is beneficial to the customers. Even customers should be satisfied with the post-sale service. - Competitive position

Six sigma team not only works on the quality of the product but its sustainability too. This makes your organization in a competitive position in the industry. Here competition doesn’t limit to the organization, but to individual employee career. Once you are certified with six sigma green belt law, you are a tough competition to your colleagues. - Boost Individual Profile

Six sigma green belt certification will be an edge to any individual career. If you’re someone who is interested in working on projects, and on the critical analysis part of the project. The analysis doesn’t limit to only profit but to quality management, brand building, etc. Once you gain experience in all these areas of the project. You can expect an excellent salary, high managerial position in the industry. - Brand building and development

As we mentioned before that six sigma doesn’t limit profit. The six sigma team works on customer satisfaction, validation of the product, market credibility. They analyze everything with the help of tools to measure the brand with a bell graph.

In the current competitive market, it is very important to have the brand value and trust of your stakeholders. One crisis can ruin everything your brand name, stakeholders, profit. Six Sigma certified team builds brand value and keeps track to make it sustainable.

How to make graph upward is the specialist of the six sigma team. - Process Continuity

Six sigma team job doesn’t end with the launch of the project. They check the performance of the project and post reviews of the market. Whether target customers is satisfied with the product or service. Is there any defect or error in the project minor or major? How to eliminate the error or defect? If the project is successful, how long will it satisfy the customer’s needs? When to work on the new project, how it will satisfy the customer requirements. - Increase your leadership quality

In the six sigma green belt certification course located, they train you to be a leader. They

provide you practical knowledge before stepping into the industry as a professional. So once you are certified six sigma green belt, you are eligible for a higher post in the project. This gives you a different level of confidence to handle the crisis, analysis of performance, management. - High demand among the industry

There is a big competition in the market for hiring the best employees. The six sigma green belt certificate will make you on the prior list for the recruiter. The more you be a part of the project management in operations, your experience will increase your demand. You can apply in different sector of industries such as project manager, process engineer, manufacturing engineer, Continuous improvement specialist, six sigma consultant, operational excellence manager, mechanical engineer, reliability engineer and the list goes on.

Visit Our Other Course:

Lean Six Sigma Green Belt Certification Training

45-min online masterclass with skill certification on completion

Mentored By Chetan Bhagat

$99 FREE

Access Expires in 24Hrs

Upcoming Batches of Six Sigma Green Belt Certificate :-

| Batch | Mode | Price | To Enrol |

|---|---|---|---|

| Starts Every Week | Live Virtual Classroom | 19500 | ENROLL NOW |

Best Academy for Six Sigma Green Belt Certification Course

Henry Harvin

Henry Harvin is known as one of the best academies for Six Sigma Green Belt Certification Course. Henry Harvin provides complete practical training for operation management.

In Henry Harvin, they combine lean and DMAIC METHODOLOGY to work best in key skills. HENRY Harvin already worked on 12 projects.

In Henry Harvin, you can choose both online and offline classroom options. This flexibility brings more learners to grab the opportunity. Henry Harvin is affiliated with Project Management Institute. In Henry Harvin, you will get 100% practical knowledge. They follow the popular GCAO pedagogy method of training. You will be trained by the award-winning trainer. This helps with more experimental learning. This is the oldest course in South Asia. You can get access to 33 PDUs claimed by PMI.

You will get live projects, recorded videos for a year. After completing the course from Henry Harvin, you can apply for the internship with them. Here they will train you for getting a good job profile in the field. You will get weekly job notifications. A wide job opening opportunity is waiting for you. They will provide you a monthly brush-up sessions.

Henry Harvin is trusted by the best corporates such as Abbott Pharma, Avon Cosmetics, SAB Miller, Apollo Tyres, HostBooks, Inc., NTPC, l Deloitte, Fidelity Investments and by 12+ IIMs , including IIM Ahmedabad, IIM Bangalore, and IIM Calcutta and 7+ IITs, including IIT Bombay and IIT Delhi.

Read About: Six Sigma Green Belt Course In Delhi

Benefits of Six Sigma Green Belt for Organization

- Minimize Waste

- Customer Satisfaction and Retention

- Reduce unnecessary cost

- Higher profit and higher return

- Brand development

- Boost employees confidence

- Build customers and stakeholders trust Benefits of Six Sigma Green Belt Certification for Employees

- Profile Building

- Career Development

- Effective Management Skill

- Leadership Quality

- Handling the crisis

- Research and Analysis

Case studies on Six Sigma Implemented Projects

Reference : https://pecb.com/article/six-sigma-a-case-study-in-motorola

PECB Logo

/ Resources

/ Articles

Six Sigma: A Case Study in Motorola

Quality Management System

2017-11-17

A Six Sigma Overview - Nowadays, organizations are constantly striving to understand and meet the customer’s expectations by focusing on the quality of the products offered. Luckily, there are many tools and techniques available which enable management to improve the quality of their products and services. Six Sigma has proven to be one of the most successful tools in this regard. Six Sigma is a methodology that uses specific principles and mechanisms that ensure excellence within the organization. The ultimate goal of this methodology is to create products or services with less than 3.4 defects per million products or services produced. Witnessing its benefits, many of world’s most famous and successful organizations have decided to implement and integrate Six Sigma principles in their business processes.

Read About: Six Sigma Green Belt Course In Chennai

- The Beginning of Six Sigma

A look back in history indicates that the implementation of Six Sigma principles was pioneered by Motorola Company in 1980s. Motorola has always been a high tech company, offering highly reliable products. However, by 1970, every business in which Motorola was engaged in, was already targeted by Japanese.

During that time, Motorola, like many other American companies, was struggling to keep

up with Japanese competition. Motorola’s customers were unhappy with the product defects and customer support. On the other hand, Japanese had already built an amazing quality standard that many American companies simply could not keep up with. As a result, dealing with severe financial pressure, Motorola had to take action.

The top management summoned the Motorola engineers and sought to reduce the amount of errors in their products before they were even shipped out of their factories.

They combined all the quality management practices known till that time and created a methodology that would be the baseline of Motorola’s quality improvement program. Bill Smith, an engineer and scientist at Motorola, developed a methodology that would reduce the amount of product defects. He created the original statistics and formulas nitiated the implementation of Six Sigma methodology. Convinced in the huge success that this methodology would have, he presented the ideas to CEO Bob Galvin. Bob came to recognize this approach as the solution to their quality concerns. They followed the four phase Six Sigma methodology (measure, analyze, improve and control) and started their journey of documenting their key processes, aligning those processes to customer requirements, and installing measurement systems to continually monitor and improve these processes.

As a result, Motorola’s performance improved instantly. However, even though they were doing well, the analysis revealed that Japanese were still way ahead of them.

Thus, to remain competitive, top management vowed to make improvements in their quality by tenfold over a five-year period. Initially, this seemed to be impossible, but by the end of 1985, everyone in Motorola had started working toward that goal.

By the end of the five year period, every business in Motorola had reached their targeted scale of improvement. Motorola managers decided to fly to Japan to better evaluate how their competition was doing, and what they found out was mind-blowing.

They saw that the Japanese companies were doing 2000 times better than them. This was due to the fact that Japanese had been using similar technologies for a longer period of time.

The information unveiled in Japan changed the objectives of Motorola again. The executives became even more ambitious, and decided to set a tenfold target one more time, but deadline was set for a two year period now. Motorola goal for 1992 was to have 3.4 defects per million opportunities.

After implementing Sig Sigma, Motorola realized how important the methodology had been in improving their processes. In fact, they have documented more than $16 billion in saving as a result of Six Sigma adoption. Therefore, they decided to make the methodology public for every company that wanted to adopt it in their processes. Since then, tens of thousands of companies around the world have been considering Six Sigma as a way of doing business.

Bearing in mind the previous points, it can be concluded that Motorola implementation of Six Sigma has been a stepping stone in modern times of quality improvement.

We may wonder where will the Six Sigma journey lead us to. This path, however, will certainly be challenging while we seek perfection. But the highly satisfied customers, motivated employees, increased benefits, among many other reasons, lead to believe that the employment of Six Sigma as the best business support will never cease to exist.

Read About: Six Sigma Green Belt Course in Hyderabad

- Small Business Case Study

https://www.sixsigmadaily.com/case-study-six-sigma-small-business/

Well, in October 2017, three people asked that same question. They conducted a study,

and they published their findings in the Advances of Mechanic Engineering section of

SAGE Journals.

Two of the authors – Murilo Riyuzo Vendrame Takao and Iris Bento da Silva – work in mechanical engineering at the University of São Paulo, in São Carlos Brazil. The other author, Jason Woldt, teaches management classes at the University of Wisconsin- Platteville. They put their heads together to create a comprehensive study on the effects of Six Sigma, as it applied to one specific small-to-medium-sized enterprise…

A plumbing product distribution business.

Read About: Six Sigma Green Belt Course in Kolkata

- Spoilers: Six Sigma works.

It has worked for huge businesses like General Electric, and it still works for small- and medium-sized enterprises (SMEs) like your neighborhood lemonade stand.

“This article uses a case study highlighting the implementation of Six Sigma methodology in a North American manufacturer of plumbing products (SME). Each step of the process is properly described, and the results are also presented,” the authors said.

Check For More Relevant Articles: https://reviewsreporter.com

Recommended reads

- Six Sigma Course in Singapore

- Six Sigma Course in USA

- Six Sigma Course in Chennai

- Six Sigma Course in Bhopal

- Six Sigma Courses

FAQs

Q-1. How Six Sigma is beneficial for an organization?

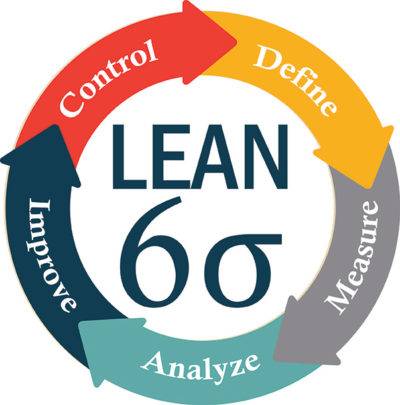

Six Sigma follows DMAIC methodology i.e. Define, Measure, Analyze, Improve and Control. This helps in eradicating errors and defects. It saves cost derived from wastage plans.

Q-2. How Six Sigma Green Belt Certification is beneficial for employees?

If you are looking for growth and willing to work as a project leader or manager. You must do the six sigma green belt certification course.

They train you to analyze and criticize the situation. In training, you get practical knowledge and experience, which you can apply in the future.

Q-3. Which Academies are best for the six sigma certification course?

You can do the course from one of the finest institutes Henry Harvin, Grey Campus, and so on. For that, you can do some research online.

Q-4. Why one should opt for six sigma in an organization?

Six sigma basically helps in promoting the profit of an organization. It also keeps customer satisfaction and needs in mind. It is a highly disciplined methodology and well-structured tools

Q-5. How many belts are there in Six Sigma?

There are three belts in the Six Sigma Yellow Belt, Green Belt, and Black Belt. All these indicate the stages you clear.

Yellow belt stands for basic knowledge of six sigma techniques.

Green Belt stands for advanced level of six sigma tools and technology.

Six Sigma Black Belt Course stands for the one who cleared all the stages. It is a complete training of six sigma course.

Q-6. Who can apply for the six sigma green belt course?

One must hold a minimum of 3years of experience in the relevant field. It should be a full time paid role. Interns or free landing jobs don’t count for this course.

Q-7. Does the Six Sigma Certificate Expire?

No, it doesn’t have an expiry date. Once you clear the course and examination, you will be certified by the six sigma certification council.

Q-8. what is the duration of the six sigma certification course?

It takes around 2wks to 7wks to complete as a green belt holder of six sigma certification. Depending upon the level you apply to.

Q-9. Six Sigma certification course is online or offline?

The training and examination both are online. So it is convenient for you to apply for the course with your current job. It examines your proficiency in handling the fundamental process of the organization.

Q-10. What is six sigma?

The six sigma is basically a bell graph where three are above the mean and the remaining three below three. You study all this with the help of tools and techniques used in the six sigma certification course.

Every organization’s goal is to earn profit and create brand value. Six sigma helps to achieve those goals by eliminating and eradicate waste and validation. It reduces the cost of production and increases productivity. In today’s scenario, it is very important for an organization to have six sigma-certified employees. For the employees, it is important to add up the course with relevant field experience for better growth and performance.

Recommended Programs

Lean Six Sigma Green Belt

Certification Training

Ranked No.1 Six Sigma Certification in India | Aligned to IASSC Book of Knowledge | Combining Lean and DMAIC Methodology to Impart Key Skills | Gain Experience of 12+ Projects | Both Classroom and Live Online Options Available

Lean Six Sigma Black Belt

Certification Training

Ranked No.1 Six Sigma Black Belt Certification in India | 9361+ Participants Trained | Aligned to IASSC Book of Knowledge (BOK) | Gain Advanced Expertise Over Lean and Six Sigma Methodology| Gain Experience of 12+ Projects | Both Classroom and Live Online Options Available

Lean Six Sigma Master

Black Belt Certification

Step-in to a new designation of being Explicit Quality Professional | Get acknowledged as a Lean Six Sigma Evangelist | Connect to the rarest community of worldwide Black Belt specialists | Validate your professional skills in leading intricate projects | Execute Lean methodologies with perfection.

Explore Popular CategoryRecommended videos for you

E&ICT IIT Guwahati Best Six Sigma Green Belt Program

Ranks Amongst Top #5 Upskilling Courses of all time in 2021 by India Today

View Course

.webp)